We are manufacturer, supplier and distributor of Inconel 718 Blocks, ASTM B166 Inconel 718 Blocks, ASME SB166 Inconel 718 Blocks, 2.4668 Blocks.

Renine Metalloys LLP has emerged as a prominent manufacturer, supplier, and stockist of metal blocks, delivering precision-engineered products to diverse industrial and manufacturing sectors. With a decade of expertise in metal fabrication and processing, the company specializes in providing high-quality metal block solutions that meet the demanding requirements of tool and die making, engineering, aerospace, automotive, and heavy machinery industries.

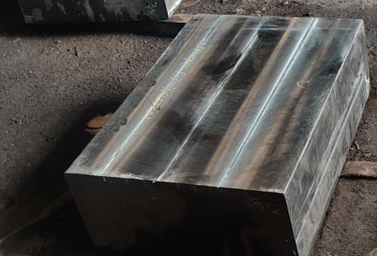

As a leading metal block manufacturer, Renine Metalloys LLP produces an extensive range of blocks in premium materials including stainless steel blocks, carbon steel blocks, alloy steel blocks, tool steel blocks, aluminum blocks, and brass blocks. The company's state-of-the-art machining and cutting facilities ensure that every metal block is manufactured with precise dimensional accuracy, flat surfaces, and square edges. From standard rectangular blocks to custom-sized industrial blocks, the manufacturing capabilities accommodate varied specifications for applications ranging from precision tooling to structural components.

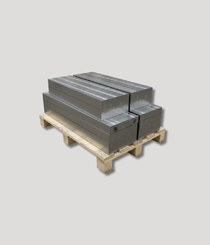

Renine Metalloys LLP maintains substantial inventory as a comprehensive metal block stockist, ensuring immediate availability of products in multiple sizes, grades, and thicknesses. This strategic stock management enables quick turnaround times for clients with urgent project requirements and bulk orders. Whether customers need solid blocks, hardened blocks, ground blocks, or custom-cut blocks, the company's versatile production capabilities and extensive inventory ensure seamless fulfillment of orders across different industrial sectors.

Quality control is the cornerstone of Renine Metalloys LLP's operations. Each metal block undergoes thorough inspection including dimensional verification, flatness testing, hardness testing, surface finish analysis, and material composition verification. This rigorous quality assurance process guarantees that clients receive products conforming to international standards such as ASTM, DIN, IS, JIS, and BS specifications, making them ideal for critical machining and fabrication applications.

Understanding the specific requirements of industries utilizing metal blocks for die making, jigs and fixtures, gauge blocks, wear plates, and precision components, Renine Metalloys LLP offers expert technical consultation. The company's engineering team provides valuable guidance on block specifications, material selection, heat treatment requirements, and application-specific recommendations, ensuring customers receive optimal solutions for their manufacturing challenges.

With competitive pricing, superior product quality, certified materials, and efficient pan-India delivery capabilities, Renine Metalloys LLP stands as your reliable partner for all metal block requirements, supporting manufacturing excellence through precision products and exceptional service.

Inconel 718 Blocks Supplier, ASTM B166 Inconel 718 Blocks Manufacturer, ASME SB166 Inconel 718 Blocks Stockist, 2.4668 Blocks Distributor, UNS N07718 Blocks Exporter

Specifications

| Standard | ASTM, EN, DIN, IS, JIS |

| Form | Solid Block / Rectangular / Square |

| Size Range | 20 mm to 1000 mm (Width & Length) |

| Thickness / Height | 5 mm to 500 mm |

| Manufacturing Process | Forged / Machined / Cut from Plate |

| Surface Finish | Mill Finish, Pickled, Machined, Polished |

| Tolerance | ±0.1 mm or as per customer requirement |

| Hardness | As per grade & heat treatment |

| Corrosion Resistance | Excellent (Grade dependent) |

| Temperature Resistance | Up to 870°C (Grade dependent) |

| Applications | Machine Components, Tooling, Structural Parts, Dies |

| Industries Served | Oil & Gas, Power Plant, Engineering, Chemical, Marine |

| Testing | PMI, Chemical, Dimensional, Hardness |

| Customization | Size, Grade, Finish as per drawing |

| Packing | Wooden Box / Pallet / Export Packing |

Available type of Blocks

Inconel 718 Closed Die Forged Block

ASTM B166 Inconel 718 Custom Forged Block

ASME SB166 Inconel 718 Die Block

UNS N07718 Forged Block

2.4668 Forged Blocks

ASTM B166 Inconel 718 Open Die Forged Block

ASME SB166 Inconel 718 Solid Block

Inconel 718 Square Block

Equivalent

| STANDARD | Inconel 718 |

|---|---|

| UNS | N07718 |

| WERKSTOFF NR. | 2.4668 |

| JIS | NCF 718 |

Chemical composition

| Element | Composition |

|---|---|

| Nickel (Ni) | 50.00 – 55.00 |

| Carbon (C) | 0.08 maxx |

| Manganese (Mn) | 0.35 max |

| Copper (Cu) | 0.30 max |

| Sulfur (S) | 0.15 min |

| Silicon (Si) | 0.35 max |

| Chromium (Cr) | 17.00 – 21.00 |

Stock available at our warehouse

| Inconel 718 Square Blocks | EN Custom Forged Blocks |

| ASTM B166 Inconel 718 Rectangular Blocks | Inconel 718 Hollow Blocks |

| ASME SB166 Inconel 718 Solid Blocks | 2.4668 Closed Die Forging Blocks |

| 2.4668 Forged Blocks | JIS Ncf 718 Cold Forging Blocks |

| UNS N07718 Rolled Blocks | ASTM B166 Inconel 718 Custom Fabricated Blocks |

| JIS Ncf 718 CNC Machined Blocks | Gost Upset Forging Blocks |

| BS Rough Machined Blocks | BS Drop Forging Blocks |

| Afnor Precision Ground Blocks | Afnor Impression Die Forging Blocks |

| Gost Cut-to-Size Blocks | UNS N07718 Hot Forging Blocks |

| EN Heavy Thickness Blocks | ASME SB166 Inconel 718 Open Die Forging Blocks |

Industries We Serves

Chemical industries

Desalination plant

Oil and Gas

Petroleum Refinery

Pharmaceutical industries

Refinery plant

Flanges

block

Testing Facilities