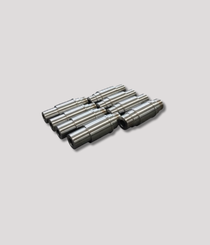

We are manufacturer, supplier and distributer of UNS S31600 Eccentric Shaft, ASTM A276 SS 316 Cold Forged Shaft, ASME SA479 SS 316 Propeller Shafts.

Renine Metalloys LLP stands as a leading shaft supplier, manufacturer, and stockist in India, delivering precision-engineered shafts for diverse industrial applications. With years of expertise in metallurgical excellence, we specialize in manufacturing high-quality shafts that meet stringent industry standards and customer specifications. Our comprehensive range includes motor shafts, pump shafts, gearbox shafts, drive shafts, turbine shafts, rotor shafts, and custom-engineered shaft solutions for various industrial sectors.

World-Class Shaft Manufacturing Capabilities

As a prominent shaft manufacturer, Renine Metalloys LLP operates state-of-the-art manufacturing facilities equipped with advanced CNC machines, precision turning centers, grinding machines, and quality testing equipment. Our manufacturing process incorporates cutting-edge technology ensuring dimensional accuracy, surface finish excellence, and superior mechanical properties. We manufacture shafts from premium materials including stainless steel, alloy steel, carbon steel, duplex steel, mild steel, and specialized nickel alloys, catering to specific application requirements and environmental conditions.

Our shaft stockist facility maintains extensive inventory of standard and customized shafts in various dimensions, grades, and specifications. This strategic stock availability ensures immediate delivery, reducing your procurement lead time and minimizing production downtime. Renine Metalloys LLP understands the critical nature of shaft components in industrial machinery, which is why we prioritize stock maintenance and rapid dispatch capabilities across India and international markets.

Comprehensive Shaft Product Range

Renine Metalloys LLP offers an extensive portfolio of shaft products as a reliable shaft supplier:

Motor Shafts: Precision-manufactured motor shafts for electric motors, servomotors, and industrial drive systems with accurate keyway cutting and balanced construction.

Pump Shafts: Corrosion-resistant pump shafts designed for centrifugal pumps, submersible pumps, and industrial pumping applications with enhanced fatigue resistance.

Gearbox Shafts: Heavy-duty gearbox shafts manufactured with precise spline cutting, gear mounting surfaces, and hardened zones for power transmission systems.

Drive Shafts: Robust drive shafts for automotive, agricultural, and industrial machinery with superior torsional strength and dynamic balancing.

Turbine Shafts: High-precision turbine shafts for steam turbines, gas turbines, and hydro turbines engineered for high-speed rotation and thermal stability.

Conveyor Shafts: Durable conveyor shafts and roller shafts for material handling systems with anti-corrosive coatings and customizable lengths.

Propeller Shafts: Marine-grade propeller shafts manufactured from corrosion-resistant alloys suitable for maritime and offshore applications.

Custom Shafts: Bespoke shaft solutions designed and manufactured according to client drawings, specifications, and unique application requirements.

Quality Assurance & Technical Specifications

At Renine Metalloys LLP, quality is paramount. As a certified shaft manufacturer and supplier, we implement rigorous quality control measures throughout the production cycle. Our shafts undergo comprehensive testing and inspection procedures including:

- Dimensional inspection using Coordinate Measuring Machines (CMM) and precision measuring instruments

- Ultrasonic testing (UT) for internal defect detection and material integrity verification

- Magnetic particle inspection (MPI) for surface crack detection

- Hardness testing to verify material properties and heat treatment effectiveness

- Surface finish analysis ensuring optimal performance and reduced wear

- Straightness measurement using precision straightness checkers

- Balancing and alignment verification for rotating shafts to prevent vibration

- Material composition analysis through spectrometry

We manufacture shafts in diameter ranges from 10mm to 1000mm and lengths up to 12 meters, with custom machining capabilities for unique specifications. Our shafts are produced in various grades including EN series, AISI grades, DIN standards, and customer-specified material compositions. Surface treatments available include chrome plating, hard chrome plating, nickel plating, heat treatment, induction hardening, and specialized coatings for enhanced performance.

Manufacturing Standards & Certifications

Renine Metalloys LLP adheres to international manufacturing standards and quality management systems. Our shaft manufacturing processes comply with ISO standards, ensuring consistent product excellence, complete traceability, and documented quality records. Every shaft leaving our facility is accompanied by material test certificates, dimensional inspection reports, and quality assurance documentation.

Our technical team comprises experienced metallurgists, mechanical engineers, and quality control specialists who ensure that every shaft meets or exceeds specified requirements. We utilize premium raw materials sourced from certified mills and suppliers, guaranteeing material authenticity and performance reliability.

Stock Availability & Delivery

As a dedicated shaft stockist, Renine Metalloys LLP maintains substantial inventory across various shaft types, sizes, and material grades. Our warehouse facilities are strategically organized for efficient stock management and quick order processing. Standard shafts are available for immediate dispatch, while custom-manufactured shafts are delivered within committed timeframes.

We serve clients across automotive, power generation, manufacturing, marine, oil and gas, chemical processing, textile, paper and pulp, mining, and general engineering sectors throughout India and globally.

Contact Renine Metalloys LLP

Partner with Renine Metalloys LLP, your reliable shaft supplier, manufacturer, and stockist for superior quality products, competitive pricing, and exceptional service. Contact us today for detailed product catalogs, technical specifications, quotations, and delivery schedules.

BS 316S31 Hollow Shaft stockist, , JIS SUS 316 Flange Shaft manufacturer, UNS S31600 Eccentric Shaft supplier, Afnor Z7Cnd17‐11‐02 Machine Shaft distributor, EN X5Crnimo17-12-2 Stepped Shaft exporter.

Specifications

| Standards | ASTM, EN, DIN, IS, JIS |

| Form | Round / Solid Shaft |

| Diameter Range | 6 mm to 500 mm |

| Length | Up to 6 meters (Cut length as required) |

| Manufacturing Process | Hot Rolled / Cold Drawn / Forged / Machined |

| Surface Finish | Black, Bright, Turned, Ground, Polished |

| Tolerance | h9 / h11 or as per customer requirement |

| Straightness | As per ASTM / DIN |

| Heat Treatment | Solution Annealed / Quenched & Tempered (Grade dependent) |

| Hardness | As per grade & heat treatment |

| Corrosion Resistance | Excellent (Grade dependent) |

| Operating Temperature | Up to 870°C (Grade dependent) |

| Applications | Motor Shafts, Pump Shafts, Drive Shafts, Machine Components |

| Industries Served | Oil & Gas, Power Plant, Engineering, Marine, Chemical |

| Testing | PMI, Chemical, Mechanical, Dimensional |

| Customization | Diameter, Length, Grade, Finish as per drawing |

| Packing | Wooden Box / HDPE Wrap / Export Packing |

Available Types of Shafts

ASTM A276 Axle Shafts

UNS S31600 Cold Forged Shaft

ASME SA479 Crank Shafts

Werkstoff Nr. 1.4401 Eccentric Shaft

JIS SUS 316 Flange Shafts

EN X5CrNiMo17-12-2 Hollow Shaft

BS 316S31 Machine Shaft

Afnor Z7CND17-11-02 Stepped Shafts

Equivalent

| STANDARD | WERKSTOFF NR. | JIS | UNS | BS | AFNOR | GOST | EN |

|---|---|---|---|---|---|---|---|

| SS 316 | 1.4401 / 1.4436 | SUS 316 | S31600 | 316S31 / 316S33 | Z7CND17‐11‐02 | – | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

Chemical composition

| Nickel | 10 – 14 |

| Carbon | 0.08 max |

| Manganese | 2 max |

| Phosphorus | 0.045 max |

| Sulfur | 0.030 max |

| Silicon | 1 max |

| Chromium | 16 – 18 |

| Molybdenum | 2 – 3 |

Stock available at our warehouse

| Afnor Z7Cnd17‐11‐02 Pump Shafts | EN X5Crnimo17-12-2 Motor Shafts |

| 1.4401 Stepped Shaft | UNS S31600 Flange Shaft |

| BS 316S31 Propeller Shafts | 1.4401 Gearbox Shafts |

| UNS S31600 Hollow Shaft | EN X5Crnimo17-12-2 Eccentric Shaft |

| EN X5Crnimo17-12-2 Drive Shafts | BS 316S31 Machine Shaft |

| BS 316S31 Drive Shafts | Afnor Z7Cnd17‐11‐02 Motor Shafts |

| 1.4401 Flange Shaft | Afnor Z7Cnd17‐11‐02 Drive Shafts |

| BS 316S31 Conveyor Shafts | UNS S31600 Pump Shafts |

| BS 316S31 Cold Forged Shaft | 1.4401 Conveyor Shafts |

| Afnor Z7Cnd17‐11‐02 Axle Shafts | BS 316S31 Turbine Shafts |

Industries We Serves

Chemical industries

Desalination plant

Oil and Gas

Petroleum Refinery

Pharmaceutical industries

Refinery plant

Flanges

block

Testing Facilities