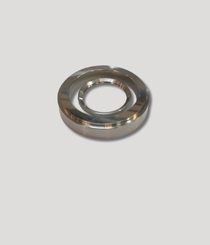

We are manufacturer, supplier and distributor of Stainless Steel 430 Rings, SS 430 Rings, Grade 430 Rings, ASTM A276 SS 430 Rings.

Renine Metalloys LLP has established itself as a premier manufacturer, supplier, and stockist of metal rings, delivering precision-engineered products to diverse industrial applications. With a strong foundation in metallurgical excellence, the company specializes in producing high-quality industrial rings that meet the exacting standards of modern manufacturing, engineering, and heavy machinery sectors.

As an experienced metal ring manufacturer, Renine Metalloys LLP produces a comprehensive range of rings in various materials including stainless steel rings, carbon steel rings, alloy steel rings, and forged steel rings. The company's sophisticated manufacturing facility utilizes advanced forging, machining, and heat treatment processes to create metal rings with exceptional strength, durability, and dimensional precision. Every product is engineered to withstand demanding operational conditions across industries such as automotive, aerospace, oil and gas, power generation, and heavy equipment manufacturing.

The company's extensive inventory as a dedicated metal ring stockist ensures prompt availability of products in multiple sizes, grades, and specifications. Whether clients require seamless rings, rolled rings, or custom-manufactured rings, Renine Metalloys LLP's flexible production capabilities and substantial stock levels guarantee timely delivery for both standard and specialized requirements. This positions them as a dependable ring supplier capable of handling urgent orders and bulk quantities with equal efficiency.

Quality assurance is paramount at Renine Metalloys LLP. Each industrial rings undergoes comprehensive testing including dimensional inspection, hardness testing, grain structure analysis, and surface finish verification. This rigorous quality control process ensures that every forged ring and machined ring meets or exceeds international standards such as ASTM, DIN, IS, and BS specifications, providing clients with products they can trust for critical applications.

Renine Metalloys LLP's technical expertise extends beyond manufacturing. The company's engineering team provides expert consultation on ring specifications, material selection, and application-specific requirements, ensuring customers receive optimal solutions for their unique challenges. Whether for bearing rings, gear rings, flanged rings, or custom rings, the company delivers tailored products that enhance operational efficiency.

With competitive pricing, robust quality standards, and efficient pan-India delivery network, Renine Metalloys LLP stands as your reliable partner for all metal ring requirements, supporting industrial excellence through superior products and exceptional service.

Stainless Steel 430 Rings Supplier, UNS S43000 Rings Manufacturer, Grade 430 Rings Stockist, ASTM A276 SS 430 Rings Distributor, ASME SA479 SS 430 Rings Exporter.

Specifications

| Standard | IS, ASTM, DIN, EN, BS |

| Type | Flat Ring, Forged Ring, Machined Ring |

| Outer Diameter (OD) | 10 mm to 3000 mm |

| Inner Diameter (ID) | As per drawing / requirement |

| Thickness | 1 mm to 200 mm |

| Manufacturing Process | Forged / Rolled / Machined |

| Surface Finish | Mill Finish, Pickled, Polished, Mirror Finish |

| Tolerance | As per ASTM / DIN or Customer Requirement |

| Hardness | As per material grade |

| Corrosion Resistance | Excellent (Grade dependent) |

| Temperature Resistance | Up to 870°C (Grade dependent) |

| Applications | Flanges, Bearings, Seals, Gaskets, Pressure Vessels, Heavy Engineering |

| Industries Served | Oil & Gas, Chemical, Power Plant, Marine, Construction |

| Customization | Size, Grade, Finish as per drawing |

| Country of Origin | India |

| Testing | PMI, Hardness, Dimensional, Chemical |

| Packing | Wooden Box / Pallet / Export Packing |

Available Types of Rings

ASTM A276 SS 430 Bright Forged Ring

UNS S43000 Forged Rings

Grade 430 Forging Ring

JIS SUS 430 Hot Forged Rings

BS 430S21 Plate Cut Rings

ASME SA479 SS 430 Rolled Rings

Grade 430 Seal Rings

JIS SUS 430 Seamless Rolled Ring

Equivalent

| Standard | SS 430 |

|---|---|

| UNS | S43000 |

| WERKSTOFF NR. | 1.4016 |

| JIS | SUS 430 |

Chemical composition

| Element | Composition |

|---|---|

| Carbon (C) | ≤ 0.12 % |

| Chromium (Cr) | 16.0 – 18.0 % |

| Silicon (Si) | ≤ 1.00 % |

| Phosphorous (P) | ≤ 0.040 % |

| Sulphur (S) | ≤ 0.030 % |

| Nickel (Ni) | ≤ 0.75 % |

Stock available at our warehouse

| Stainless Steel 430 Rolled Forged Rings | Grade 430 Compressor Wear Rings |

| SS 430 Seamless Forged Rings | ASTM A276 SS 430 Valve Seat Rings |

| Grade 430 Open-Die Forged Rings | ASME SA479 SS 430 Valve Backing Rings |

| ASTM A276 SS 430 CNC Machined Rings | UNS S43000 Inner Bearing Rings |

| ASME SA479 SS 430 Precision Machined Rings | BS 430S21 Outer Bearing Rings |

| UNS S43000 Slip-On Flange Rings | JIS SUS 430 Expansion Rings |

| BS 430S21 Weld Neck Flange Rings | Stainless Steel 430 Retaining Rings |

| JIS SUS 430 Blind Flange Rings | SS 430 Heat Resistant Rings |

| Stainless Steel 430 Lap Joint Flange Rings | Grade 430 Application-Specific Engineered Rings |

| SS 430 Metal Seal Rings | ASTM A276 SS 430 Ring Type Joint (RTJ) Rings |

| Grade 430 Pressure Seal Rings | ASME SA479 SS 430 Forged Seamless Rolled Rings |

| ASTM A276 SS 430 High-Temperature Seal Rings | UNS S43000 Customized Forged Rings |

| ASME SA479 SS 430 R-Type Rings | BS 430S21 Precision Forging Rings |

| UNS S43000 RX-Type Rings | JIS SUS 430 Large Diameter Forged Rings |

| BS 430S21 BX-Type Rings | Stainless Steel 430 Forged Rings with Machining |

| JIS SUS 430 Plain Spacer Rings | SS 430 Rolled Forging Rings |

| Stainless Steel 430 Custom Spacer Rings | Grade 430 Hot Rolled Rings |

| SS 430 Pump Wear Rings | ASTM A276 SS 430 Seamless Rolled Rings |

Industries We Serves

Chemical industries

Desalination plant

Oil and Gas

Petroleum Refinery

Pharmaceutical industries

Refinery plant

Flanges

block

Testing Facilities